The process of prestige

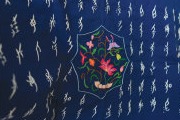

Guangdong gauze, once a luxury reserved for the wealthy, can take months to make due to its time-consuming production and the use of natural materials, Yang Feiyue reports.

Growing allure

As she mastered the craft, Ouyang's understanding of the fabric's allure deepened.

"The base material of xiangyunsha is mulberry silk, a protein fiber known for its breathability, softness and comfort, while using yam sap not only imparts a unique color to the fabric, but also endows it with medicinal properties such as hemostatic and antiallergic effects," she explains.

When she traveled to major cities like Shanghai and Jiangsu province's Suzhou, Ouyang found widespread misunderstanding and misinformation about xiangyunsha.

"Many people don't know what authentic, high-quality xiangyunsha is," she says.

During the early 2010s, the market saw a surge in imitations as machine production enabled the creation of xiangyunsha within a mere three to four days. These low-cost, low-quality products severely affected traditional workshops.

Ouyang realized it was imperative to preserve xiangyunsha through branding and standardization.

In 2018, she and her mentor Liang cofounded the brand Tangxian.

"We focus on fabric production, with 90 percent of the materials made using traditional methods," she says, adding that her company strictly follows the ancient dyeing process — three steams, nine boils, and being sun-dried 18 times.

The brand has developed over 50 types of fabric based on traditional techniques, with products ranging from clothing and shoes to accessories like hats and handbags.

Her company also developed a tracing system that records each step of the fabric's production process.

"By scanning a QR code, buyers can see exactly how their xiangyunsha was made — down to the weather report on the days it was sun-dried and the specific location where the drying took place," she says.