The process of prestige

Guangdong gauze, once a luxury reserved for the wealthy, can take months to make due to its time-consuming production and the use of natural materials, Yang Feiyue reports.

The production process for xiangyunsha is time-consuming and involves multiple rounds of dyeing and sun-drying.[Photo provided to China Daily]

As an increasing number of young people appreciated the craft, she began livestreaming in 2021 on Douyin, where she shares details of the craft. The company landed big orders, with the largest worth more than 1 million yuan ($138,000).

"My fan base is growing, too. Many drop by from all over the country," she says.

Chen Shaofeng, a professor from Peking University, says the Tangxian brand has effectively promoted the integration of the fabric with modern life, products and aesthetics.

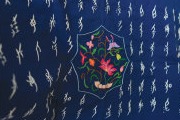

He considers it a good move to carry forward xiangyunsha, which is "one of the few silk fabrics in the world dyed using purely natural ingredients".

Wang Shousong, executive director of the EU Culture Administration, is impressed by xiangyunsha and the culture behind it.

"It carries forward China's exceptional tradition of handmade artistry, showcasing the essence of Chinese history, culture and art through embroidered patterns that reflect its depth and richness," Wang says.

Ouyang's years of experience have underscored the significance of grasping the contemporary market's requirements for xiangyunsha.

Despite this, she says it must not compromise the original quality of traditional craftsmanship.

"The charm of xiangyunsha lies in its handmade craftsmanship, the use of plant-based dyes, and absence of chemical additives," she says.

Once these elements are altered, the fabric's uniqueness and exclusivity will be lost, she adds.

Ouyang and her team are developing a wider range of patterns and exploring techniques like fruit and plant dyeing.

"There's still room to grow," she says.